Road Tripping: Visiting New Holland With Paul Kahan, Part 2

By Chuck Sudo in Food on Jun 16, 2009 3:20PM

(This is the second in a series following the evolution of a beer dinner at the Publican, from conception to reality. Read Part 1 here.)

Wednesday, June 3. 9 a.m. - I fueled up on a quick continental breakfast at the hotel across the street from New Holland’s brewpub with Brad Fuller of Paramount Merchants. Paramount Merchants is a broker between breweries and distributors. Fuller and his partner, John Barbaras, represent New Holland to the wholesalers and were instrumental in introducing Kahan and McAvena to Bueltmann, Haggerty and the other New Holland folks. When we get to the pub, Kahan was already there, coffee in hand, waiting. Haggerty was also at the pub, doing work on a laptop. McAvena followed shortly after with his girlfriend. Bueltmann was the last to arrive, with muffins for the crew.

Upon arriving in Holland the day before, we were given a tour of the brewpub by Bueltmann, Haggerty and New Holland pub brewer Jeff Sheahan. Although Haggerty would stay at the brewpub offering expertise and answering technical questions about the brewing process, the task of supervising Kahan and McAvena during the brewing was Sheahan’s responsibility. Kahan and McAvena would be brewing the bière de garde on the brewpub’s equipment, and Haggerty told me, “This brewhouse is Jeff’s system. He knows its tics and how it operates better than I do”. The week of Kahan’s visit coincided with New Holland’s preparation for its annual “Hatter Days” event and Sheahan was putting the final touches on the twelve different versions of Mad Hatter the brewery serves during the event. If it wasn’t the ideal time for Kahan and McAvena to brew on Sheahan’s system, he didn’t let it show.

New Holland’s brewpub has one mash tun and boiler, set up in the middle of the pub for customers to watch the brewing in action. Located in the basement is the grain miller/elevator setup, a whirlpool to remove any solids from the mash, four conditioning tanks for fermentation, a bright tank for clarification of the beer, and a series of lagering tanks. The grain is milled in the basement to break the malt up and allow for easier mashing. The grain elevator moves the grist to a holding tank located above the mash tun, which is pre-heated with water to 120°F.

Once the tun is pre-heated, the grain is sprayed with hot water and added to the tun. More hot water is added to bring the temperature to 145°F. The hot water extracts the sugars from the malt, creating the wort that will be boiled. Mashing the grain is a fast process, taking about 15 minutes. Once the mashing is complete, the wort mixture is transferred to the boiler. Over the course of the next 90 minutes, the wort is boiled and more hot water is added, a process called sparging. Impurities such as chlorine imparted from the water are boiled off in the first 30 minutes. Other additives are added during the final 30 minutes to balance any remaining impurities from the water.

It’s during the wort boiling where the hops are added. New Holland, like the majority of breweries, buys their hops as processed pellets. “There are three ways to add hops to beer: whole hops, pellets or hop extract”, Haggerty explained. “Whole hops (Note: Sierra Nevada works with whole hops) are hard to work with because the solid remains can clog your whirlpool. Hop extract is just hops in liquid form, but costs a bit more than pellets. You can’t really tell the difference between extract and pellets.”

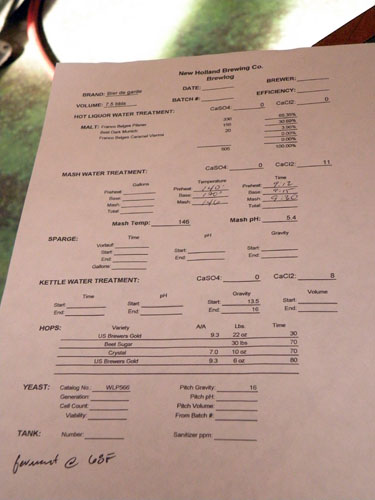

When the boiling is complete, the wort is transferred to the whirlpool to remove any remaining solids, then through a heat exchanger which brings the temperature of the wort down from 140°F to 65°F in a matter of seconds, where it's sent to a sanitized conditioning tank with yeast already added. Haggerty’s bière de garde recipe was tailored to yield 7.5 barrels of beer (about 14-15 half-barrel kegs). Haggerty decided upon brewing with Franco Pilsner, Dark Munich and Caramel Vienna malts.

The Munich malt is key, as this is where the beer will get its color and sweetness. Hops are a combination of U.S. Brewers Gold and Crystal, with 30 pounds of beet sugar added for the Saison yeast to feast on, fermenting the wort. Half of the yield is to be given to the Publican for the dinner, with the rest to be served at New Holland’s brewpub.

Sparging the grain began around 10 a.m. With Sheahan watching, McAvena and Kahan took turns stirring the mash with a boat oar to prevent clumping and maximize extraction. Within minutes the brewpub was flooded with a fragrant, pleasant aroma of sweet malt. Sheahan smiled and exclaimed, "This is the best smell of the day." By 11, the mash was slowly transferred to the boiler. There, it was further stirred during boiling.

What I discovered was that there is a lot of waiting during brewing. While Kahan and McAvena were keeping tabs on the boil, Sheahan and Haggerty were checking the gravity of the wort using a hydrometer and a refractometer, respectively. The hydrometer is a weighted, thermometer-like gauge that floats when inserted in liquid, indirectly determining the amount of sugar in the mash. The refractometer is a device where a layer of mash is spread across a slide. The brewer then looks into a viewfinder to determine the density of the mash itself on a Plato scale.

Sheahan also spent the boiling time making the connections for the whirlpool, sanitizing the conditioning tank, and preparing the yeast mixture. While Sheahan was doing that, Kahan and McAvena began cleaning out the spent grain from the mash tun. I noticed Kahan sampling some of the grain and asked how it tasted. “There’s nearly nothing there”, he replied, “which is what I would expect.” I took a sample myself and, indeed, there was almost no flavor there. The mashing had extracted nearly all the sugar from the grain. After the whirpool removed any remaining solids, the beer will stay in the conditioning tank for a minimum of six weeks, aging and fermenting. Sheahan will transfer it to the bright tank for final clarifying, then it'll be sent to kegs and prepped to transport to Chicago

By 4 p.m. Sheahan was in the final stages of cleanup. “During a standard work day I’m usually having to clean up later because I left a connection open or forgot something”, he said. “But I went over this day in my head every day for about a week, to make sure nothing went wrong.”

And did it?

“Not at all. Here it is, 4 p.m. and I have an hour to spare." Sheahan would take advantage of that hour, as would we, when we made it to our accommodations for the night. Bueltmann had set up something special in honor of Kahan’s visit.

To be continued...